Containerised Incinerators

Low maintenance, all-in-one waste management solution for sites.

Pre-Assembled

Pre-plumbed and wired, requiring minimal on-site installation.

Plug & Play

Simply connect water, fuel and electricity to initiate operations.

Containerised

10', 20' and 40' sized containers available.

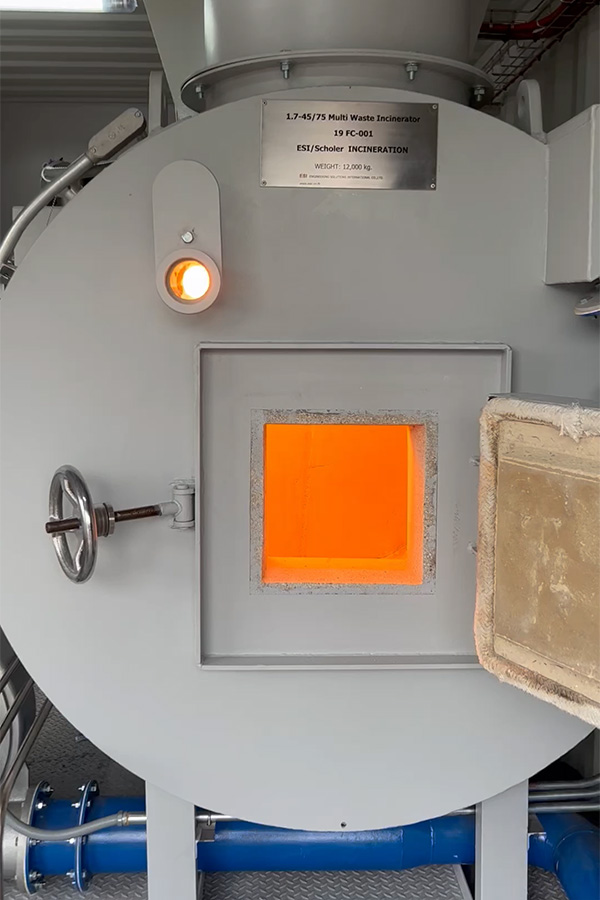

Fully contained, all-in-one solution for incineration

With the unique capability to load IBC’s and cyanide boxes directly into the unit, ESI’s Containerised Incinerator is engineered for the safe disposal of hazardous waste on site. Eliminating the double handling of potentially dangerous materials.

The containerised incinerator can be built within 10′, 20′ and 40′ containers with the advantage of easy shipping and installation without the need for additional construction. Perfect for gas & oil industries, gold & copper mining, incinerator for mining camp, military and remote sites with limited space and without the need to create further structures.

Built to withstand the elements, with further operator shelter provided by the container awnings once in place on site.

Waste Capacity

Engineered to manage

high CV hazardous or medical waste 15kg - 600kg/hr

and/or general waste (MSW) 25kg - 1,000kg/hr

Designed to handle IBC's, large boxes and special designed containers to suit any waste stream. For larger amounts of waste, see our Multi Waste Feed System Incinerators.

Easy Operation & Low Maintenance Design

Our containerised incinerator features a sophisticated yet user-friendly design, ensuring easy operation and minimal maintenance for remote sites.

Industries Served

Our incinerators cater to diverse sectors, serving as a simple and effective solution for remote locations or areas lacking infrastructure.

- Gas and Oil industries

- Gold and Copper mining

- Military camps

- Medical facilities

- Municipalities

Highly Efficient Combustion

Our incinerators employ partial burning with pyrolysis gasification in the Primary Combustion Chamber (PCC), followed by complete gas combustion at high temperatures within the Secondary Combustion Chamber (SCC).

Specialising in incineration, our team has unparalleled knowledge of waste leading to the development of highly efficient, customisable burn cycles and ‘smoke-free’ incinerators that meet stringent US EPA Emission Standards.

Streamline Waste Collection

Choose from our waste collection and feed options to increase waste stream management and customise the incinerator to suit your site needs.

- Front Fork Loader for IBC’s and containerised waste

- Apron Feeder for loose bulk waste

- Waste Oil Feed Injection System for reduced fuel consumption

- Screw Feed System for sludges

- Ash Drag Chain Conveyor for ash transfer to skip bins

- Fork Loader Ash Removal device

Services

Our comprehensive range of services include:

- Site visits for waste stream assessment, recommendations and waste management proposals.

- Commissioning and operator training.

- Remote access control to the incinerator for assistance and any fault finding during the life of the unit.

- Ongoing support including site visits and further training when required.

Commissioning Process

During commissioning, we focus on improving on-site efficiencies by implementing tailored preset burn cycles, customise and reduce cycle lengths and enhance waste stream management.