MINE SITE INCINERATORS

Hazardous Waste Management for the Mining Industry

Revolutionising Mine Site Waste Management with Containerised Incinerators

Mining operations generate large quantities of waste that require proper management to minimise environmental impact and ensure operational safety. Traditionally, this mining waste has been handled through landfill or chemical treatments. Incineration provides and increasingly attractive option when equipped with innovative technologies, as it can effectively handle waste efficiently.

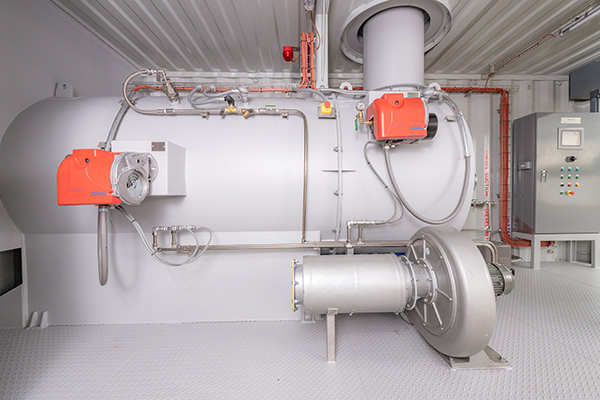

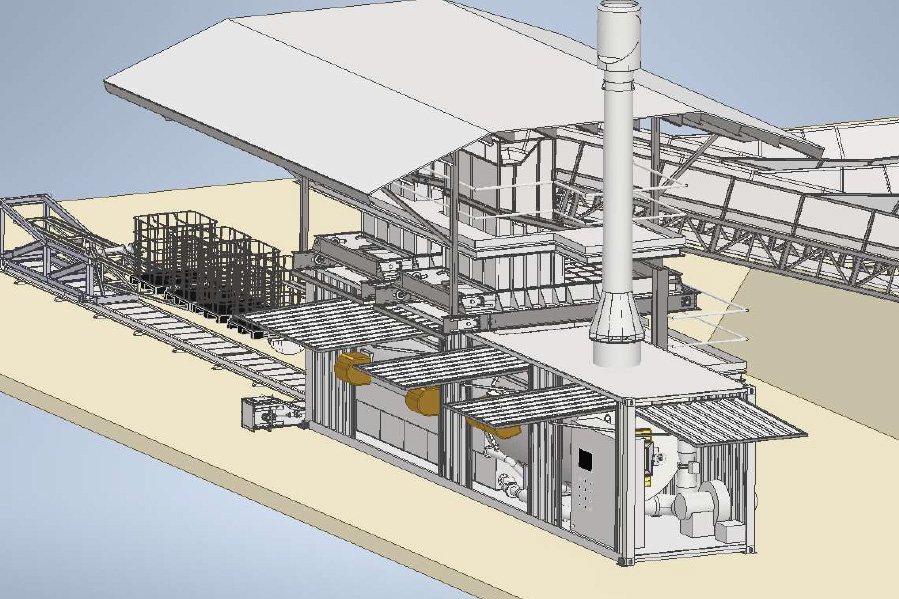

One of the most cutting-edge solutions for mining waste management today is the use of containerised incinerators with direct loading capabilities for IBC’s (Intermediate Bulk Container) and cyanide boxes and multiple waste feed systems. These advanced systems not only increase waste handling capacity but also streamline the incineration process, providing maximum efficiency and safety in mining operations.

The Challenges of Mine Site Waste

Mining generates a variety of waste streams, including:

- Hazardous chemicals used in extraction processes (e.g., cyanide, solvents)

- Contaminated equipment and protective gear

- Oily rags and sludge from machinery

- Solid waste (e.g., packaging, plastics)

- By-products from mineral extraction

Improper management and handling of these materials can lead to serious environmental contamination, affecting water sources, soil quality, and air pollution. Incineration can safely and effectively neutralise these hazardous substances, especially when they are diverse and complex in nature.

ESI offers comprehensive Site Waste Assessments identifying types of waste on site and the avenues available to safely dispose of each stream.

Delivering Maximum Performance & Benefits

Containerised incineration units provide a compact incinerator for mining camp site housed within a standard shipping container, making it easy to transport to remote or temporary mining sites. When equipped with the ability to directly load IBCs, the system offers a number of advantages for mining operations:

1. Cost Effective

Assembled within 10′, 20′ & 40′ shipping containers, Containerised Incinerators are an all-in-one waste management solution that does not require additional infrastructure, saving money on further construction. The sides of the container lift up, providing an awning and shelter for the operators.

2. Easy to Ship & Install

For remote mining sites lacking permanent waste treatment facilities, Containerised Incineration units offer an easy-to-ship, on-site solution. ESI units require only fuel, water, and electricity to operate. Housed in a shipping container, the incinerator can be relocated as the mine develops or moved to other sites, reducing long-haul waste transport costs and minimising the carbon footprint of waste management.

3. Energy Efficient

ESI’s Incinerators are programmed with burn cycles tailored to the site waste, effectively handling the material and minimising pollutant release. The Incinerators can process waste oils, designed with energy recovery capabilities, to power operations or provide heat to nearby facilities. This reduces overall energy consumption and operating costs, further enhancing the efficiency of the system.

4. Optimising Operator Safety

Mining operations frequently store waste materials in IBCs, which are durable, reusable containers capable of holding both liquids and solids. ESI’s large incinerator doors are specifically designed to load IBC’s and Cyanide boxes direct, eliminating double handling of hazardous materials. This reduces handling time and the risk of spills or worker exposure to toxic substances.

5. Faster Waste Processing

Direct loading IBC’s and large boxes, ensures that bulk waste materials can be fed into the incinerator in one seamless process, reducing the need for pre-processing or waste sorting. This increases throughput and enables the system to manage large waste volumes efficiently. Dispose of cyanide boxes and filled IBC’s.

ESI can help establish efficient waste management systems for teams on site to ensure waste components are split into suitable streams to reduce handling, eliminate manual labour, and speed up the overall incineration process.

6. Reduced Downtime

A key feature of incineration is the ability to process multiple waste streams simultaneously, essential for mining operations with varied waste types. This flexibility allows different waste categories (e.g., liquid chemicals, solid hazardous materials, combustible debris) to be incinerated within the same unit, boosting efficiency, reducing downtime, and enabling continuous operation.

The Environmental and Economic Benefits

By using a containerised incineration unit with IBC loading and multiple waste feeds, mining operations can reduce their reliance on traditional landfill and chemical waste treatments, which often carry higher environmental risks and costs. Incineration eliminates waste at the source, leaving behind only a small volume of sterile ash that is easier and safer to dispose of.

- Reduced Transportation Costs: Mobile units reduce the need to transport waste over long distances to external treatment facilities, cutting fuel costs and reducing the carbon footprint of the waste management process.

- Environmental Compliance: Incineration systems can effectively handle hazardous waste, meeting strict environmental regulations and helping mining companies demonstrate a commitment to sustainable practices.

Applications of Containerised Incineration Units in Mining

These innovative systems are ideal for various applications within mining operations:

- Remote mining sites where access to traditional waste treatment facilities is limited.

- Exploration projects that generate waste temporarily, requiring a mobile and flexible solution.

- Mining camps and housing that produce both hazardous and non-hazardous waste in high volumes.

- Tailings management for dealing with hazardous by-products from the extraction process.

Mining waste incineration using containerised units with direct IBC loading and multiple waste feed systems represents a major advancement in waste management technology. These units offer a versatile, easy to ship, and highly efficient solution that can safely and effectively handle large volumes of diverse waste types, while reducing operational costs and environmental impact. By investing in such systems, an incinerator for mining camp can optimise waste handling processes, improve safety for workers, and contribute to more sustainable mining practices.