Multi Waste Feed System Incinerators

Customisable waste management solutions for larger waste loads.

Unlimited Waste Feeds

Streamline waste collection on site with our range of Waste Feed Systems

Plug & Play

Simply connect water, fuel and electricity to initiate operations.

Customisable

Fully customisable to suit diverse waste types & large waste quantities.

Multi Waste Feed System Incinerators

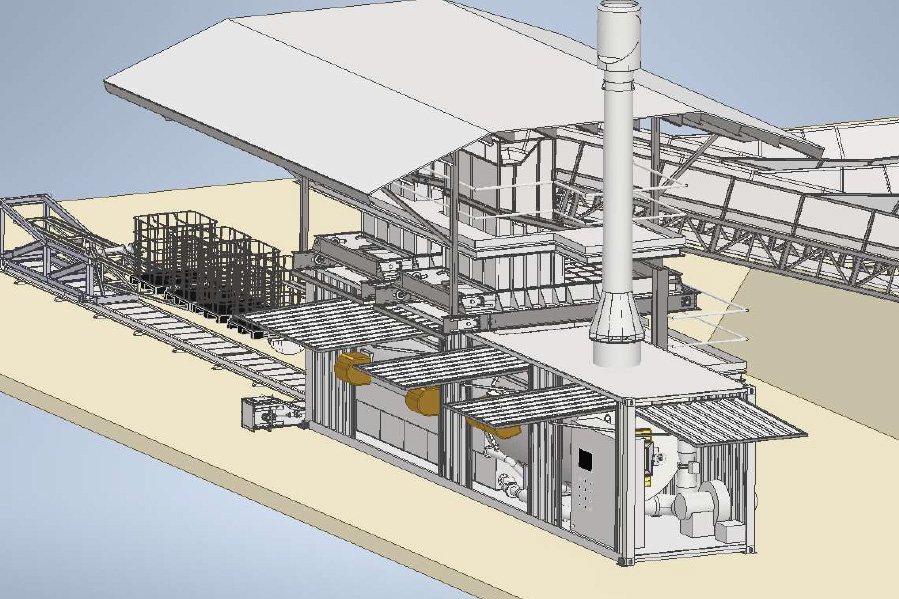

Multi Waste Feed System Incinerators cater to the diverse needs of site waste and are fully customisable to suit a range of waste feeds. Engineered to handle larger waste loads, perfect for gas & oil industries, gold & copper mining, military. Suited to remote sites with limited space and without the need to create further structures.

Built to withstand the elements, with further operator shelter provided by the container awnings once in place on site.

Minimal Operator Handling

All of our systems are designed and engineered for minimal operator handling of waste. No shredding, no double handling, no decanting of liquids etc. ensuring ease of operation on site.

Waste Capacity

Engineered to handle larger volumes of high CV hazardous or medical waste.

Designed to handle IBC's, large boxes and special designed containers to suit any waste stream.

See our Containerised Incinerators for waste loads under 600kg/hr.

Reference Site:

Santos, PNG.

This Multi Waste Incinerator, nicknamed ‘The Beast’, was commissioned for Oil Search Limited in the Southern Highlands of PNG in 2016 to handle the entire site’s hazardous waste, including vehicle tyres.

Engineered for 1,000kg/hr, the 4IBC unit features a 36 cubic metre primary chamber and three waste loading systems:

- Two Top Apron Feeders for loose bulk waste

- Front Fork Loader for containerised waste

- Waste oil and liquids sprayed into the SCC, reducing fuel consumption of the incinerator.

ESI made use of the natural fall of the site, situating the unit beside a hill, reducing the length of the two Apron Feeders to transition waste into the incinerator.

Combustion Process

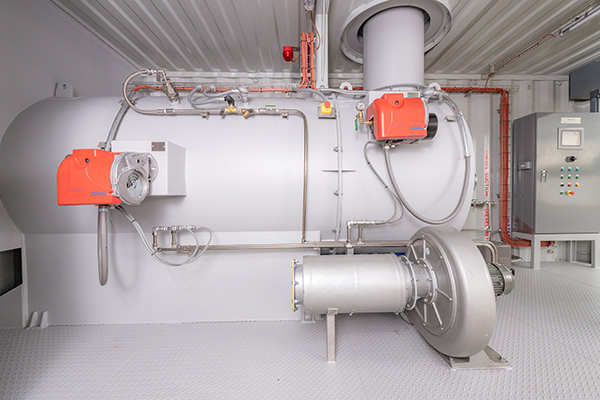

ESI’s incinerators employ partial burning with pyrolysis gasification in the Primary Combustion Chamber (PCC), followed by complete gas combustion at high temperatures within the Secondary Combustion Chamber (SCC), meeting stringent US EPA Emission Standards.

Streamline Waste Collection

Choose from our waste collection and feed options to increase waste stream management and customise the incinerator to suit your site needs.

- Front Fork Loader for IBC’s and containerised waste

- Apron Feeder for loose bulk waste

- Waste Oil Feed Injection System for reduced fuel consumption

- Screw Feed System for sludges

- Ash Drag Chain Conveyor for ash transfer to skip bins

- Fork Loader Ash Removal device

Services

Our comprehensive range of services include:

- Site visits for waste stream assessment, recommendations and waste management proposals.

- Commissioning and operator training.

- Remote access control to the incinerator for assistance and any fault finding during the life of the unit.

- Ongoing support including site visits and further training when required.

Commissioning Process

During commissioning, we focus on improving on-site efficiencies by implementing tailored preset burn cycles, customise and reduce cycle lengths and enhance waste stream management.