Preventative Maintenance Program

Optimising Uptime

Ensuring efficient operations and uptime for our Incinerators, ESI offers a Preventative Maintenance Program. In our experience, the waste management area is not always a priority for operational support against the main production. Therefore, delays waiting on replacement parts and specialised personnel for issues that may arise can lead to a long downtime for waste operations. Our goal is to reduce the risk of waste incineration downtime while also extending the life of the equipment, resulting in a twofold cost saving in operations.

Fixed Price Service & Support

ESI offers a fixed price two year (or more) Preventative Maintenance Program, for bi-annual site visits to review all equipment and optimise operations. The service includes:

- Comprehensive checks of all incinerator equipment

- Preventative maintenance of equipment, changing out parts as required before issues arise

- Managing stock levels within spare parts store

- Software updates for Burn Cycle programming

- Updates to programs as required for managing different wastes

- Continued operator training covering operation, maintenance essentials and troubleshooting, with remote access support

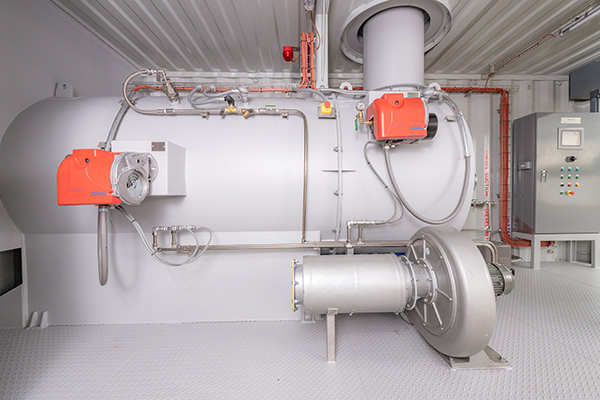

See our Containerised Waste Incinerators here.

Remote Access Support

Providing a connection direct between site operations and our team, ESI’s remote access online assistance can help diagnose and resolve topics that may arise in real time. A laptop computer is supplied to help carry out diagnostics and performance monitoring on the complete unit, so we can keep the incinerators running at peak performance.

Spare Parts Store

Managing the spare parts store for the incinerator equipment not only helps to maintain operational uptime by reducing the risk of parts wearing down and extending the life of the equipment, but also ensuring suitable stock levels so that operators don’t need to wait up to 2 months for replacement parts.

Plug & Play Burners

Continuous incinerator operation stems from the burners running effectively. To maintain uptime, ESI provide a spare plug & play burner module. This allows the operator to disconnect a burner, without waiting for electrical or mechanical services, and swap it out for the spare burner to keep the incinerators running until the next service.